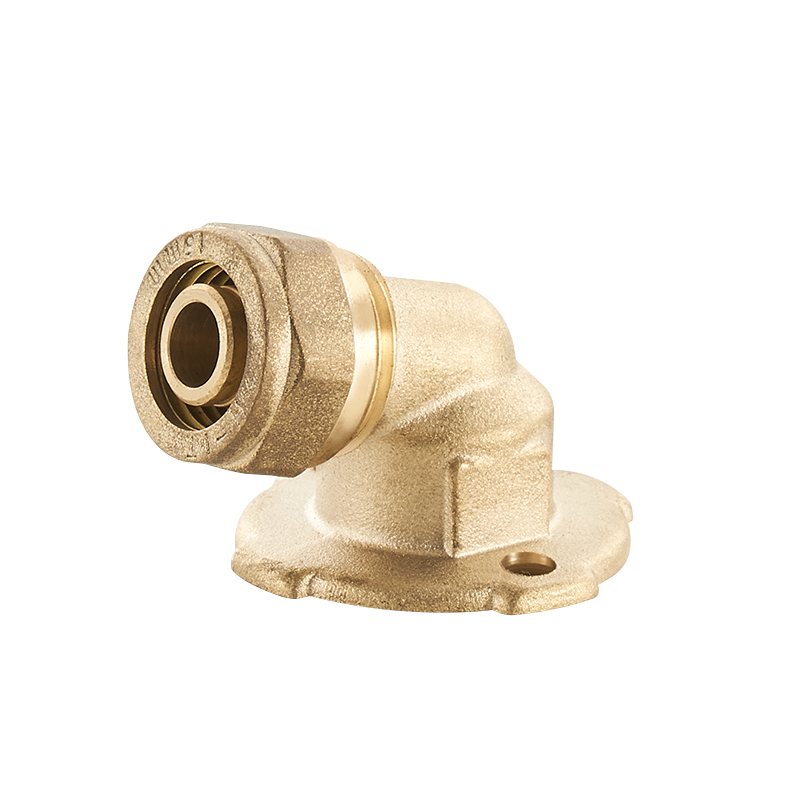

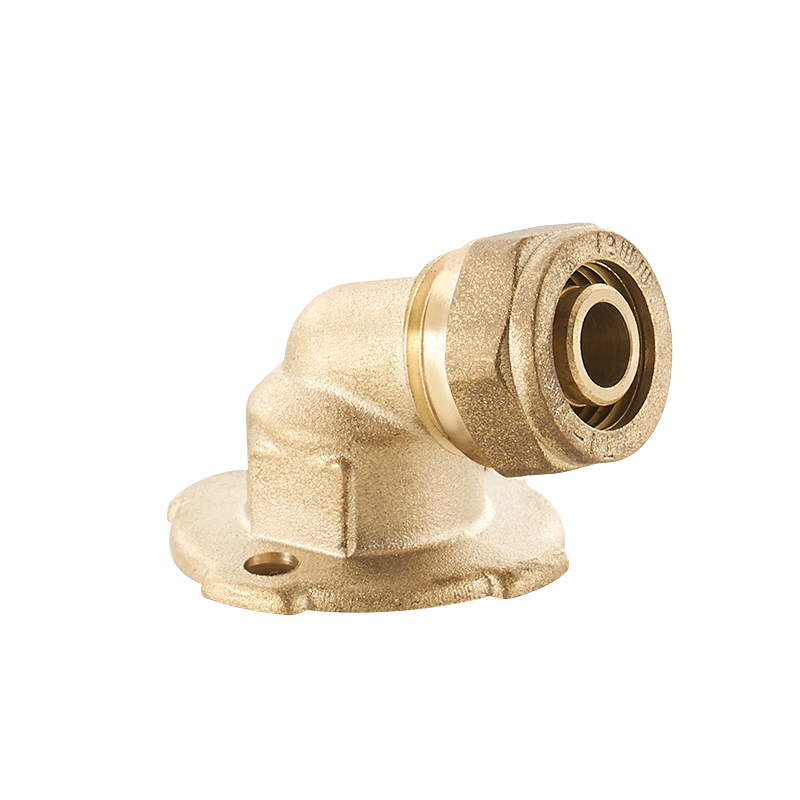

105° Wallplate Elbow Brass Compression Fitting For Pex Pipe

Optional Specification

Product Information

| Product name | Brass Wall plate Pex Fittings | |

| Sizes | 16mm x 1/2" ×2.2mm | |

| Bore | Standard bore | |

| Application | Water, oil, gas, and other non-corrosive liquid | |

| Working pressure | PN16 / 200Psi | |

| Working temperature | -20 to 120°C | |

| Working durability | 10,000 cycles | |

| Quality standard | ISO9001 | |

| End Connection | BSP, NPT | |

| Features: | Forged brass body | |

| Precise dimensions | ||

| Various sizes available | ||

| OEM production acceptable | ||

| Materials | Spare Part | Material |

| Body | Forged brass, sandblasted | |

| Nut | Forged brass, sandblasted | |

| Insert | Brass | |

| Seat | Open copper ring | |

| Stem | N/A | |

| Screw | N/A | |

| Packing | Inner boxes in cartons, loaded in pallets | |

| Customized design acceptable | ||

Optional Materials

Brass CW617N, CW614N, HPb57-3, H59-1, C37700, DZR, Lead-free

Optional Color and Surface Finish

Brass natural color or nickel plated

Applications

Fluid control system for building and plumbing: Water,oil, Gas, and other non-corrosive liquid

When assembling pipe joints with advanced geometric design features, the front pressing is pushed into the joint body and the pressing tube to form the main seal, and the rear pressing is inward to produce a dumpling chain effect to form a strong grip on the pressing tube. Post-compression geometry contributes to an advanced engineered chain-clamp action that converts axial motion into radial compression on the compression tube, requiring only minimal assembly torque to operate .

Use of gap inspection gauge:

1. Only use the inspection gauge to check whether the joint is tight when installing the brass compression fitting for the first time.

2. Put the gap detection gauge next to the gap between the pressed nut and the body.

3. If the inspection gauge cannot be inserted into the gap, the joint is sufficiently tightened.

4. If the inspection gauge can be inserted into the gap, it means that it needs to be tightened.

Contact Us